A practical guide for pharmaceutical facilities that cannot afford guesswork

Walk into any pharmaceutical manufacturing plant at 7:00 a.m. sharp, and you’ll notice something almost theatrical. Stainless steel gleams like a mirror. Floors look surgical. Operators move with ritual-like precision. Every label, every logbook entry, every valve position feels deliberate.

That level of discipline isn’t aesthetic. It’s survival and it’s owing to the dedication to GMP Pharmaceutical Documentation.

In pharma manufacturing, “good enough” doesn’t exist. A single overlooked detail—a smudge in a transfer line, a skipped calibration, a casual shortcut—can ripple outward into recalls, regulatory warnings, or worse, compromised patient safety. With that thought, we move forward to analyse the difference between gmp and cgmp.

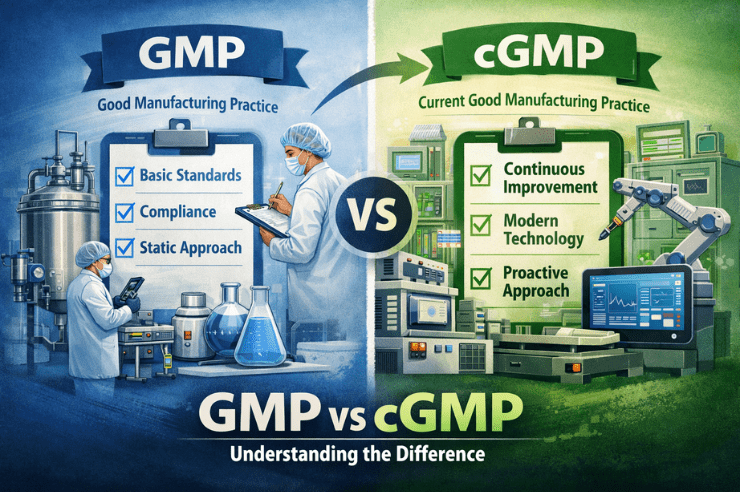

This is where two terms show up again and again: GMP and cGMP difference

cGMP vs GMP sound similar. They’re often used interchangeably in conversation. But in practice, the difference between them is the difference between meeting the bar and raising the bar continuously.

For facility providers supporting pharmaceutical companies, understanding this distinction isn’t just academic. It shapes how you design cleanrooms, choose finishes, specify utilities, and build systems that stand up to audits without breaking a sweat.

Let’s unpack it clearly.

Difference between cGMP and GMP

what is GMP?

GMP (Good Manufacturing Practice) is the foundational framework for producing safe, consistent, and high-quality pharmaceutical products.

Think of GMP as the rulebook. It defines the minimum expectations a facility must meet so that medicines are:

- Made consistently

- Free from contamination

- Properly documented

- Controlled at every stage

At its core, gmp vs cgmp answers simple but critical questions:

Is the process controlled? Is the equipment suitable? Are procedures documented? Can every batch be traced? If the answer to any of these is “no,” the system is unstable.

GMP covers areas like:

- Personnel hygiene and training

- Equipment design and maintenance

- Cleaning and sanitation

- Documentation practices

- Quality control

- Storage and distribution

It establishes order. It removes chaos. It turns manufacturing into a repeatable science rather than a gamble.

But here’s the catch.

GMP tells you what’s acceptable. It doesn’t necessarily force you to keep improving.

That’s where cGMP steps in.

What is cGMP?

The “c” in cGMP stands for current.

That one small letter changes everything.

Because “current” means:

- Not yesterday’s standards.

- Not last decade’s equipment.

- Not “it still works, so we’ll keep using it.”

It means today’s best practice.

cGMP requires companies to continuously update systems, technologies, and procedures to reflect modern expectations, evolving regulations, and improved science.

If GMP is the baseline, cGMP is the moving target.

It asks tougher questions:

- Is this equipment still the safest option available?

- Are we using outdated methods when better ones exist?

- Could automation reduce human error?

- Are cleaning processes validated to modern sensitivity levels?

- cGMP is proactive. It doesn’t wait for failure to force change.

The Real Difference Between GMP and cGMP

On paper, the cGMP and GMP difference looks small. In reality, it’s philosophical.

GMP says:

“Meet these standards.”

cGMP says:

“Meet today’s standards—and upgrade when better ones exist.”

- GMP is compliance.

- cGMP is continuous improvement.

- GMP is static.

- cGMP evolves.

- GMP prevents obvious mistakes.

- cGMP prevents future ones.

It’s the difference between maintaining a car and upgrading it with modern safety features.

Both run. Only one prepares you for what’s next.

Why This Difference Matters for Pharmaceutical Facilities

For facility providers, this distinction directly impacts design decisions.

Because buildings and process infrastructure aren’t temporary—they’re long-term investments.

Designing only for GMP can lock a facility into outdated workflows within a few years.

Designing for cGMP builds flexibility and future readiness.

That’s a big deal.

Pharma companies don’t want to renovate every five years. They want systems that age gracefully.

How GMP Shows Up in Facility Design

When designing to GMP, the focus is on establishing safe fundamentals:

- Cleanable surfaces

- Controlled environments

- Segregated production zones

- Standard HVAC systems

- Documented procedures

This ensures contamination control and regulatory acceptance.

It works. It passes inspections.

But it may not anticipate tomorrow’s expectations.

How cGMP Changes the Game for Facilities

cGMP pushes design thinking further.

Instead of asking, “Does this work?” the question becomes, “Will this still work five years from now?”

That subtle shift leads to smarter infrastructure choices:

- Modular cleanrooms that adapt to process changes

- Automated monitoring systems instead of manual checks

- Real-time environmental sensors

- Closed material transfer systems

- High-containment isolators

- Digital batch records instead of paper logs

Suddenly, the facility isn’t just compliant—it’s resilient. Audits become smoother. Deviations drop. Downtime shrinks.

It’s not just safer. It’s more efficient.

And efficiency in pharma isn’t about speed alone—it’s about fewer mistakes, fewer reworks, fewer sleepless nights.

A Quick Comparison at a Glance

Here’s a practical way to see the contrast:

GMP

- Establishes minimum standards

- Focuses on compliance

- Can remain unchanged for years

- Reactive to problems

cGMP

- Demands up-to-date practices

- Focuses on improvement

- Encourages modernization

- Prevents problems proactively

- One keeps you legal.

- The other keeps you competitive.

Where Facility Providers Add Real Value

For companies building or upgrading pharmaceutical plants, the facility partner plays a critical role. Because compliance isn’t achieved after construction—it’s baked into the design.

Choices like:

- Surface finishes

- Air handling systems

- Equipment layouts

- Flow paths for people and materials

- Containment strategies

- Cleanability

These aren’t cosmetic decisions. They determine whether a site quietly passes inspections or constantly fights deviations.

A facility designed by PDVD consultants doesn’t just meet regulations—it anticipates them.

That’s the difference between scrambling before audits and walking in calmly with documentation already airtight.

The Bottom Line

Here’s the simplest way to remember it:

GMP builds the foundation.

cGMP keeps renovating the house.

Both matter, especially for a pharmaceutical consultant in India.

But only one keeps you future-ready.

For pharmaceutical manufacturers—and the facility providers who support them—embracing cGMP isn’t extra effort. It’s risk management, reputation protection, and operational sanity rolled into one.

Because in this industry, yesterday’s “good” quickly becomes today’s liability.

And medicines, quite literally, deserve better than yesterday.